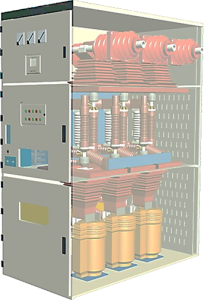

In order to adapt to the urban application of the inch of land, miniaturised compact products are developing rapidly, it is self-evident that the advantages of miniaturisation are obvious, the space occupied by the switchgear is small, the footprint, the construction cost will be reduced, the comprehensive benefits are obvious, but the miniaturised products are not equal to the energy-saving products, some of the miniaturised switchgear need a large number of solid insulating materials to cover and partition to meet the insulation requirements, and need to solve the problem of temperature rise with a large number of copper rows, resulting in increased costs and high material consumption. Some miniaturised switchgears require a large amount of solid insulating material cladding and partitioning to meet the insulation requirements, and require a large amount of copper rows to solve the temperature rise problem, resulting in increased costs and high material consumption, which are not really energy-saving and environmentally-friendly products in line with the requirements of “double carbon”. A 40.5kV miniaturised switchgear.

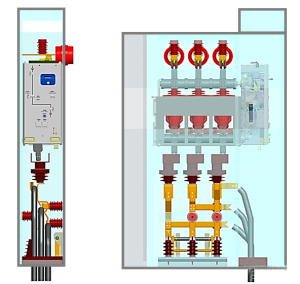

The direction of miniaturisation is to reduce materials and improve performance through optimal design and scientific analysis. Such as side-mounted longitudinal rotary switchgear, longitudinal rotation to solve the width problem. 12kV air-insulated switchgear 400mm wide, 1100mm deep, covers an area of only 30% of the general switchgear, 60% of the weight, reliable wall mounting to achieve the installation of the cabinet before the maintenance, the switchgear steel, copper use is reduced, the consumption of resources is low, to 10,000 units, for example, it can be reduced by 360 tonnes of copper rows used, the consumption of non-ferrous metals, the use of steel, the use of copper is reduced. Consumption of non-ferrous metals, steel usage is reduced by 950 tonnes; less energy consumption in the process of use, the average length of the conductive circuit per phase is 1.3 m, which is half of that of a general medium-sized cabinet (average length of the conductive circuit per phase is 2.6 m). A side-mounted longitudinal rotary transfer switchgear cabinet

Side-mounted transfer switchgear air-insulated, the volume and ring network cabinet is comparable to the parameters but can reach 1250A / 31.5kA, more importantly, does not use the greenhouse effect gas SF6, can replace the SF6 ring network cabinet to reduce the use of SF6. Taking 10,000 sets of switchgear as an example, the use of SF6 gas can be reduced by 25 tonnes, which does not include the loss of gas charging and discharging, testing, etc. in the production process.

Reliable operation of switchgear ensures the continuity of production and business activities. Switchgear operating under high voltage and high current for a long period of time, heat accumulation, insulation aging, and environmental impacts can cause accidental power outages or even accidents, resulting in huge losses. Accumulation of heat in the switchgear requires heat balance design of the switchgear to ensure that the heat generation and dissipation are the same, and the design of ventilation holes and conductive circuits is crucial, especially in high-current switchgear, where the skin effect, proximity effect, and eddy currents not only cause huge losses, but also cause safety hazards, and eddy currents can generate local overheating and vibration. Overheating causes faults, and the aging of insulation and the aggravation of local discharge are also great hazards. Eddy current generates local vibration, which can cause loose connection in long term operation.

Reliable performance in the “dual-carbon era” is even more important, the losses caused by power outages are self-evident, switchgear in a variety of different working conditions, different operation and maintenance conditions can achieve reliable operation, which is the key, such as condensation, dirty environment, environmental resistance of the switchgear has a strong environmental adaptability. Such as in the high temperature, sand and dust serious photovoltaic power station; in the salt spray corrosion, shock vibration of offshore wind power applications, all need high reliability products.

Then, such as side-mounted longitudinal rotary switchgear, move away to solve the maintenance, interchangeable needs, longitudinal rotation to solve the problem of disconnecting the visible, reliable contact, that is, there is an upper isolation and can be equipped with a lower isolation at the same time, but also can be withdrawn, to meet the various needs of the integration of mechanical interlocking is more reliable, more simple. Do not need to shake 20 turns, do not have to worry about plum contact spring collapse, disc spring contact pressure is more stable; current and voltage sensors are integrated in the solid sealing pole column, protection is installed in the circuit breaker panel, the self-deactivation to ensure that in the absence of external power supply, you can still quickly break the circuit breaker; safety valve mechanism to ensure that the trinity circuit breaker is withdrawn after the access to the cable room, maintenance, cable voltage resistance test; independent pressure relief channel Ensure the safety of the operator when the internal arc fault occurs.