GEE is committed to providing high-quality and highly reliable Vacuum Circuit Breaker (VCB) products. We insist on 100% in-house production of all machined parts to ensure product consistency and manufacturing quality. During production, we implement lean management practices, set up fixed workstations, and adopt a “one station, one box” material assembly system to significantly improve assembly efficiency and process control. Our core components—operating mechanisms and wiring harnesses—are manufactured and assembled domestically, making them our flagship products and widely recognized in the market. With rich OEM experience for leading VCB brands, our operational model has been adopted by many well-known companies.

Currently, our annual output exceeds 50,000 AIS operating mechanisms and over 7,000 VCBs, ensuring sufficient capacity and stable delivery. The company is certified under both ISO 9001 and ISO 14001 management systems. Before leaving the factory, each product undergoes 50 final operations for mechanisms and 100 operations for VCBs, along with strict inspections of materials and finished products using advanced equipment to guarantee quality and reliability. Our warehouse maintains a three-month safety stock, enabling quick response to customer demands.

These comprehensive advantages bring tangible benefits: efficient component modifications, shorter lead times, consistent product quality, and highly competitive pricing. Our VCBs are compatible with a wide range of brands, including Eaton, Baoguang, and Xuguang, offering flexible and reliable solutions for our clients.

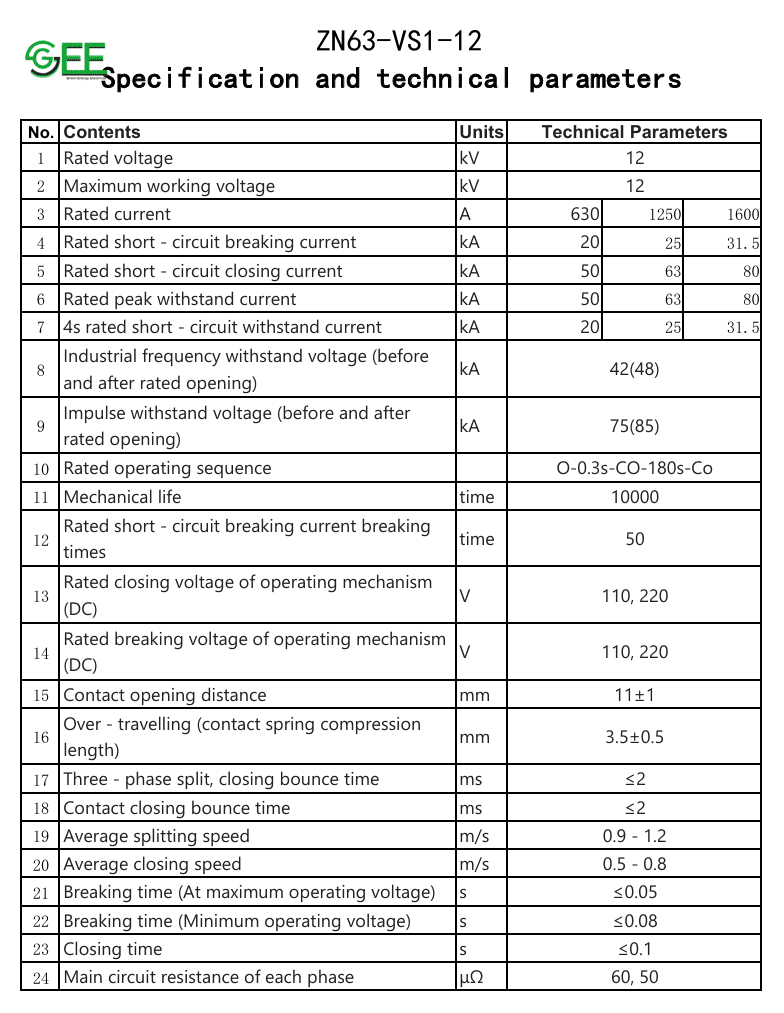

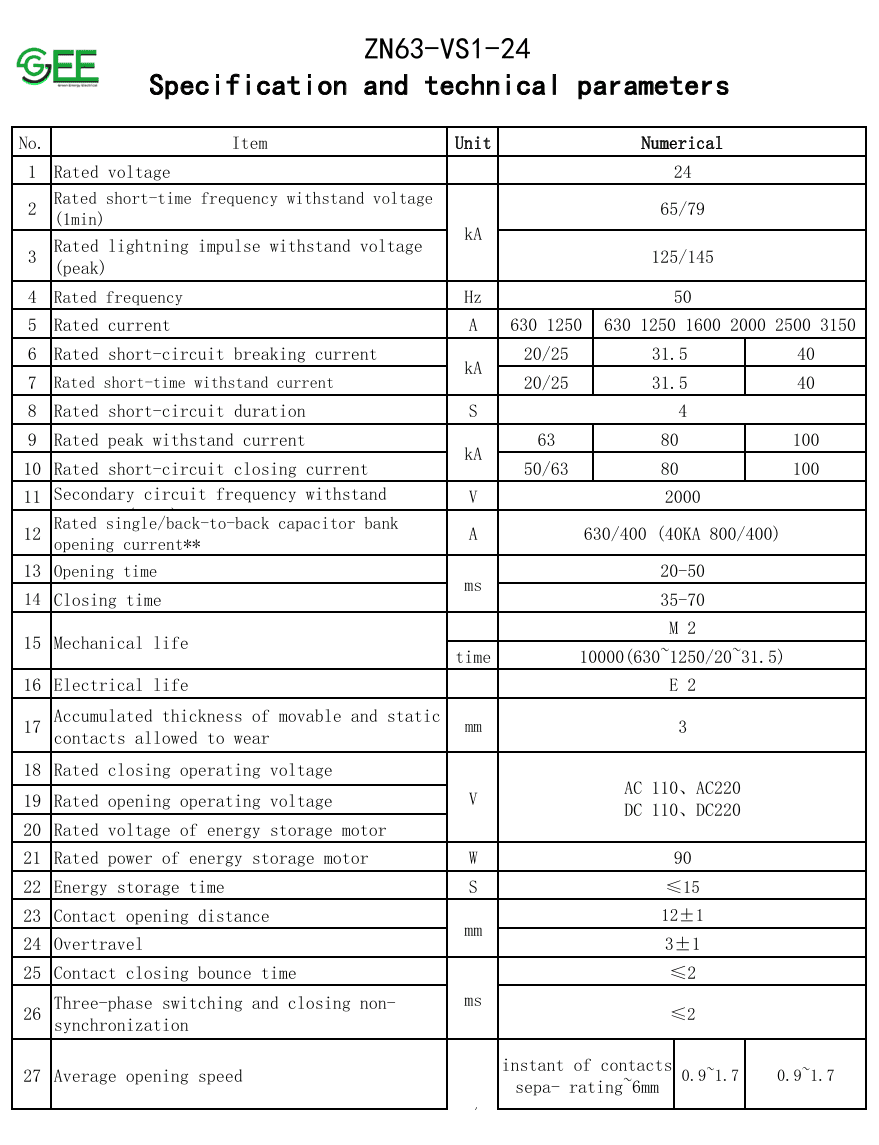

Selecting a suitable Vacuum Circuit Breaker (VCB) requires careful evaluation of key technical parameters, including rated voltage, current, short-circuit breaking capacity, and installation type. Environmental conditions, insulation design, and mechanical endurance also directly impact performance and service life. This guide outlines the essential criteria to help you choose a VCB that fits your system requirements precisely.

Embedded pole design is suitable for harsh conditions (e.g., dusty or humid environments).

Insulation sleeves are suitable for general-purpose environments.

Required switching frequency;

Expected mechanical endurance (some models support up to 10,000 operations, while the VSG series exceeds 15,000 operations);

Environmental conditions the breaker will face (e.g., temperature, altitude, pollution level).

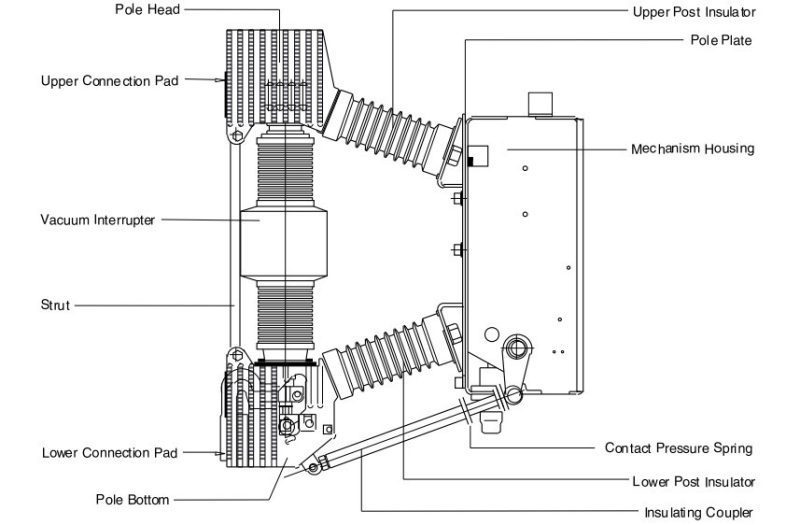

The operating principle of a Vacuum Circuit Breaker (VCB) is based on using a high-quality vacuum as the arc extinction medium. The fixed and moving contacts are enclosed within a permanently sealed vacuum interrupter. When the contacts separate, an arc forms due to the ionization of metal vapors. However, in the high vacuum environment—typically maintained between 10⁻⁷ and 10⁻⁵ torr—these metallic vapors, electrons, and ions rapidly condense onto the contact surfaces. This process ensures swift arc extinction, rapid recovery of dielectric strength, and effective current interruption. VCBs are widely used in medium voltage applications (11 kV to 33 kV) due to their reliable arc quenching capability, minimal maintenance needs, and environmentally friendly operation.

A typical VCB is composed of fixed and moving contacts, an arc shield, and a vacuum interrupter (VI), which serves as the sealed vacuum enclosure. The vacuum interrupter is hermetically sealed using stainless steel bellows to ensure vacuum integrity over its entire service life.

In medium-voltage applications, the external insulating housing is usually made of glass or ceramic. The arc shield plays a critical role in preserving internal insulation strength by preventing metallic vapors from depositing on the inner surface of the outer insulation.

The vacuum interrupter itself consists of a steel arc chamber and symmetrically arranged ceramic insulators. The moving contacts are actuated by flexible metallic bellows. Inside, the arc formed during contact separation is effectively interrupted by a magnetic field generated by the spiral-shaped contacts, ensuring reliable arc quenching and long-term operational performance.

What we provide is not just products — it is a commitment to quality, a dedication to professional service, and a partnership to help reduce costs and improve sourcing efficiency.

© 2025 Green Energy Electrical, All Rights Reserved.

Design by Zebuck